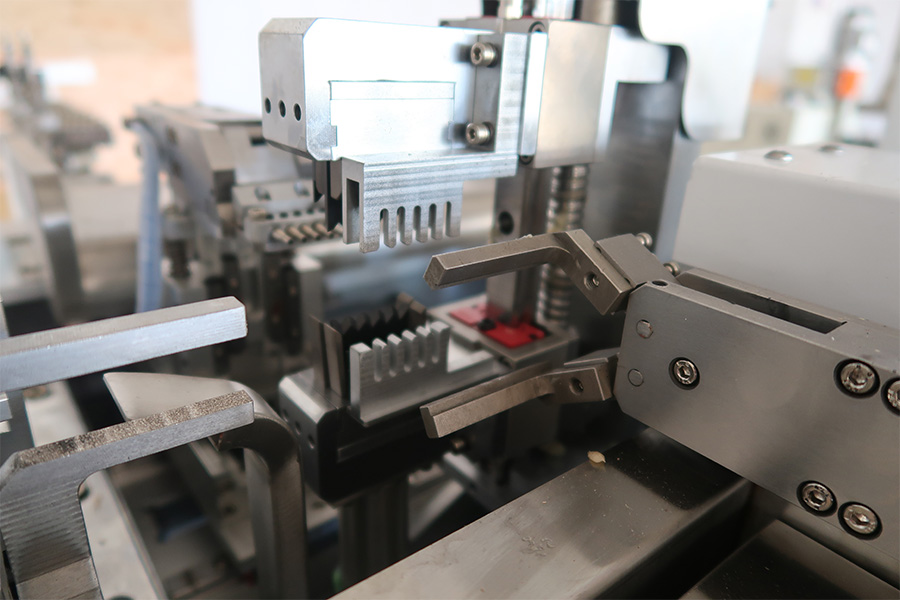

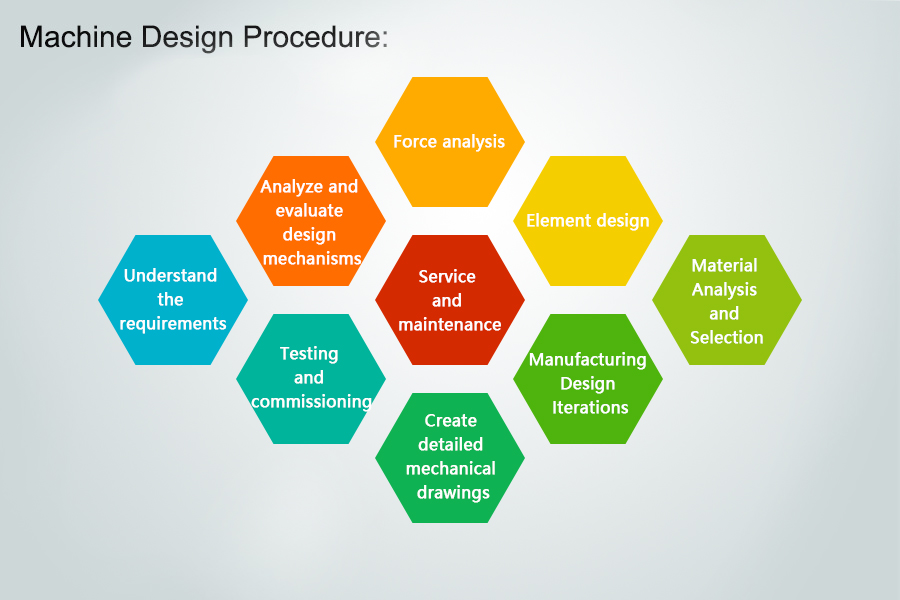

Machine Design includes topics covering elements of mechanical engineering. The design, analysis, testing and manufacture of various mechanical components such as tools, machines, mechanisms and structural systems form the basis of any industry. Machine design focuses on developing ways to increase productivity, thereby reducing unnecessary material waste or replacing it with more expensive inputs.

Machine design is an essential process in manufacturing. Its goal is to take a product idea and develop a plan to translate that idea into physical reality.

From material selection to the manufacturing process itself, there are many factors to consider in machine design. It includes creating blueprints for the machines that need to be built, as well as specifications for how those machines should operate.

In order to create effective machine designs and build machines that function properly and meet customer needs, engineers must have a thorough understanding of machine design principles.